Technologies

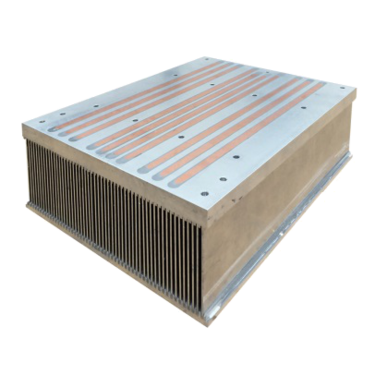

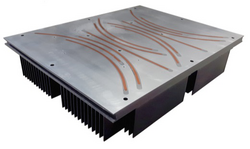

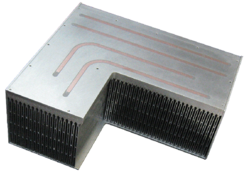

Embedded Heat Pipe Air Cooled Heat Sinks

Typical applications combine the high performance of Fabfin® and the heat spreading of heat pipes. High heat flux in concentrated areas can be spread across a heat sink by placing the hot spot over one end of the heat pipe which becomes the “evaporator” and the heat is transferred to the cooler part of the heat sink where it condenses releasing the heat to the heat sink.

Benefits

- Spreads thermal load

- Surface embedded copper heat pipes

- Integrated with Fabfin heat sinks

- Epoxy interface

Applications

Designed for for High Power Density Applications such as SiC Applications

Compared to silicon devices, SiC devices switching can exceed several 100s of kHz, offering substantial improvements in power losses. SiC devices also present enhanced power density and higher operation temperature, making them a very attractive alternative to bigger and less efficient silicon family of devices.

As the overall footprint of inverters with SiC devices shrink, the cooling aspect of the system becomes a new challenge. Mersen has been preparing for this challenge and has developed embedded heat-pipe heat sinks to extract concentrated heat from areas under the SiC devices and to disperse that heat over a larger surface area before the heat is passed on to the ambient environment. Our swaged Embedded Heat Pipe air cooled heat sinks use no glue or bonding agents for fin assembly, making them ideal for higher temperature SiC applications.

As more cooling performance is required, our cold plates provide superior cooling to ensure optimum performance of the SiC devices.