Technologies

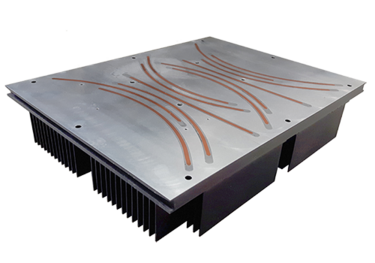

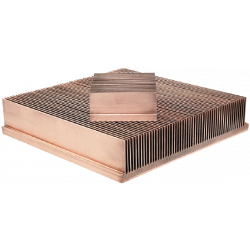

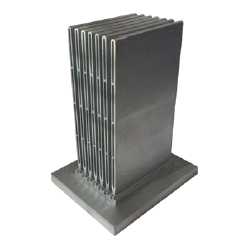

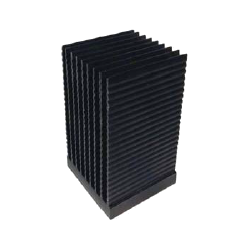

Hollowfin® and Fabfin® Air Cooled Aluminum Heat Sinks

The Fabfin heat sink stands out from ordinary extruded heat sinks because of its increased surface area, giving it excellent performance. Using a swaging process means a variety of its higher fins and increased height-to-space ratio types of fins can be used. The Hollowfin heat sink uses the same technology but the fins are doubled per fin slot to increase their density on the baseplate.

Show less

Benefits

- Multiple fins joined to baseplate by swaging process

- Metal to metal construction. Al/Al Cu/Al Cu/Cu

- No epoxy/glue used in fabrication process

- Extremely robust fabrication

- No thermal barrier at fin to baseplate joint

- Fin height to spacing ratio much greater than extrusion

- -40C to + 350C storage and operating range

- Capable of withstanding various shock and vibrations

Applications

- Communications

- Industrial controls

- Medical

- Military

- Motor drives

- Power Electronics

- Solar and Wind energy

- Transportation

Our Swaging Process - for maximum thermal conductivity!

Developed and patented by Mersen, our swaging process boosts the efficiency of air cooled heat sinks with thinner, longer fins on denser or mixed metals to get maximum thermal conductivity while keeping weight down. The swaging technology used on our Fabfin® heat sinks eliminates bonding or gluing interfaces between fins and base plate thus providing a much more robust design, suitable for use in higher operating temperature in Silicon Carbide (SiC) Applications. The glue-less swaging design ensure long life time in harsh environments.