Safe, modular and customizable battery cell connection

With battery cell type diversity, from cylindrical shapes (18650, 21700, ...) to punch and prismatic hard cases, the cell interconnection process is expected to be highly adaptable.

Mersen and F&K DELVOTEC have joined forces to combine electrical and thermal improvements, leading to a thin and single-layer laminated bus bar. Thanks to design optimizations and simulations, this technology is compatible with laser welding, allowing fast interconnection of cells.

Laser-welding at the heart of Mersen Infini∞cell

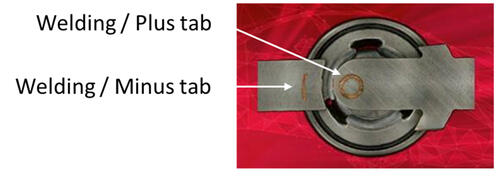

In earlier battery generation module designs, the connection between the bus bar and the cell is made by either a laser welded wire / ribbon or by ultrasonic welding. These connection methods are relatively time consuming and add to overall production cost.

To reduce cell welding process time and manufacturing cost, Mersen has developed a new and dedicated laminated bus bar design specifically developed for battery application and laser welding process: the Infini-cell® bus bar.

This new welding process is more than four times faster than the conventional combination of wire / ribbon insertion and welding method, and can provide a process time reduction of up to 60%

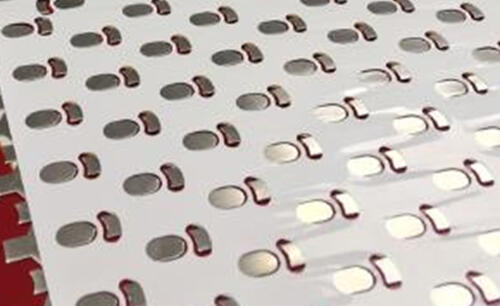

A single-layer power conductor with voltage and temperature monitoring feature

The lightweight single layer Infini∞cell bus bar solution is a combination of laminated insulation and thin conductive materials. Thanks to the thin conductive layer between 0,2 and 0,5 mm, battery cells can be easily welded to the bus bar connections using laser welding. The Infini∞cell bus bar design has two conductive layers: one for conducting power to the cells and the other layer used to monitor the status of battery cells.

The power conducting layer provides the flexibility for the OEM to design their battery cells in either series or parallel configuration, in order to efficiently reach the required voltage and power level required for their power module.

The monitoring layer of the bus bar in turn provides an embedded conductive path for temperature and voltage monitoring in specific areas of the assembly. The monitoring layer component will then typically feed the module Battery Management System (BMS). The integration of voltage and temperature sensors onto the bus bar as close as possible to the cells can lead to a better management of the complete battery assembly as well as its safer operation.

Learn more about Infini∞cell: https://ep-cn.mersen.com/products/engineering/infini-cell-battery-assembly-solutions